Advantages of Magnetic Drilling Machines

Magnetic drilling machines offer a combination of precision, safety, efficiency, and versatility that make them indispensable tools in industries that ...

Advantages of KEYLESS Drill Chuck Tool Holder

Keyless drill chucks offer several advantages over traditional keyed drill chucks, making them popular choices for various applications. Here are ...

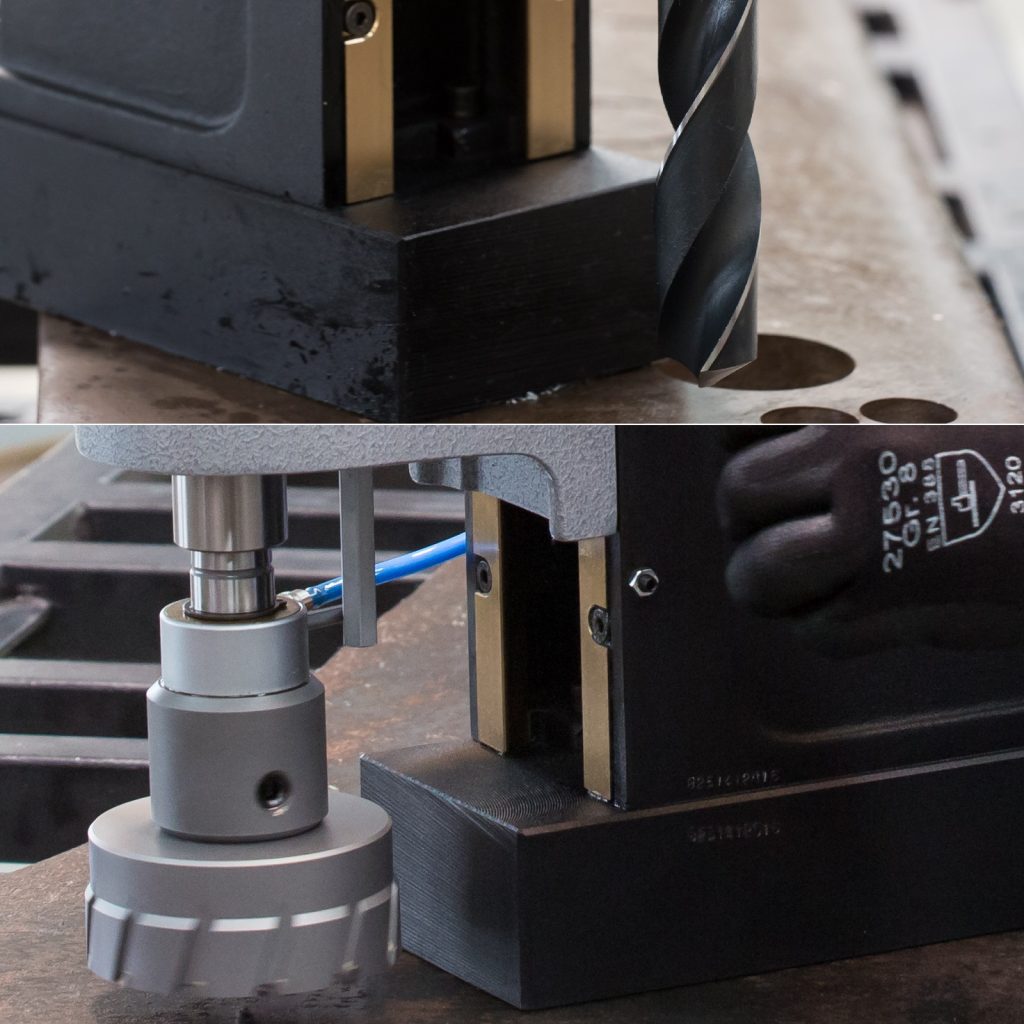

Comparing Twist Drills with Annular Cutters

Twist drills and annular cutters are both tools used for drilling holes in various materials, but they have distinct differences ...

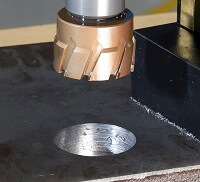

Comparison between TCT and HSS Annular Cutters

Each type has its own advantages and disadvantages, and the choice between them depends on the specific application, material being ...

Benefits of Magnetic Drilling Machine for Bridge Constructions

Magnetic drills, are versatile tools that can be beneficial in various construction applications, including bridge construction. Here are some ...