Beveling Machines Made In Germany. Next Generation Beveling & Chamfering Machines.

The new milling technology from BDS produces the best results with comfortable handling & perfect beveling.

PLATE BEVELING MACHINES

Next-generation Beveling & Chamfering Machines by BDS Maschinen GmbH, Germany. BDS manufactures mainly four types of Beveling machines as Automatic Feed Plate Beveling Machine, Portable Plate Beveling Machine, Chamfering Machines and Heavy Duty Chamfering Machines.

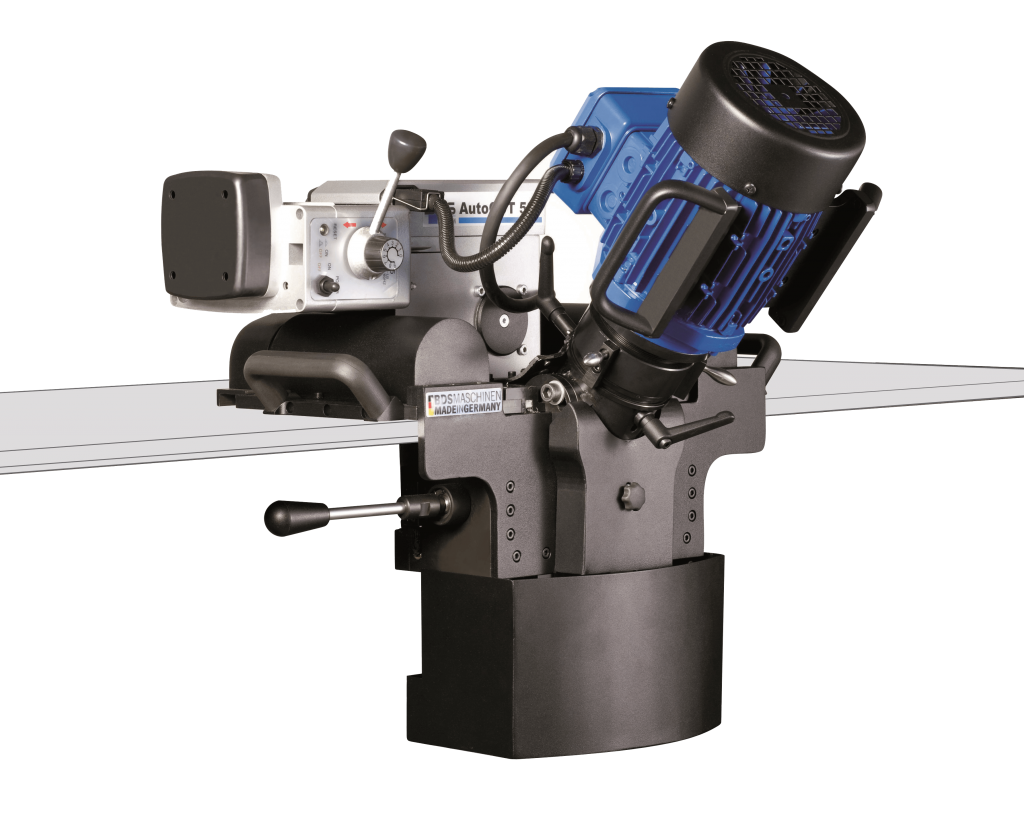

AutoCUT 500 -Fully automatic feed plate beveling machine.

Weld seam milling with automatic, seamlessly adjustable feed: quick, flexible and with a variable milling angle. The inlet/outlet rails make it exceptionally easy and safe to handle the AutoCUT 500 automatic feed plate beveling machine.

The milling angle can be adjusted seamlessly between 15° and 60°.

- Simple, safe handling

- No restriction of the working length

- No guiding carriage is needed, therefore independent from the ground conditions

- For milling plate thicknesses from 10 mm to 40 mm

- Milling cutter with 6 carbide inserts

SKF 25 -For quick and easy preparation of weld seams.

Weighing 22 kg, the SKF 25 beveling machine is easy to handle and precise to guide with smooth rollers. The result is evenly milled edges for perfect weld seams.

- Chamfer width up to 15 mm

- Seamless angle adjustment from 15° to 60°

- With ergonomic handle

- Easily guided with guide rollers

- For beveling normal steel, aluminium and non-ferrous metal

The EKF Series:

EKF 300 Series – The best entry-level series for professional chamfering & deburring operations.

In milling machines BDS incorporates new technology with no compromises, for milled edges of outstanding quality in many applications:

- Clean, even milled edge

- Exact setting of chamfer width

- Even opening angle

- Easy to use with low-strength materials

- Weld seam preparation on almost all possible contours

EKF 500 & EKF 600 Series – The high-end top of the line series.

Compact series with variable speed & full wave control electronics. The new EKF 500 & 600 series from BDS is designed for maximum performance and optimal comfort.

With the new milling head technology, the EKF machines can also operate at low speeds without jerking or jumping. The result is optimally milled edges, even when rounding. The EKF machines are ideal for deburring, bevelling and weld seam preparation.

- Variable speed control

- Carbide inserts with four cutting edges

- New ergonomic design

- Revolving supporting disc